Description

Titanium Tapered Head Socket Cap Screws Specs |

|||||||

|---|---|---|---|---|---|---|---|

| Head Style | Hex Socket Tapered | Material | Ti6AI4V (Gr.5) Titanium/Custom | LOGO | Customizable | ||

| Drive style | Hex Socket | Hardness | Rockwell C36 | Quality Control | 100% Fully Check | ||

| Thread size | M4~M36 | Thread Type | Metric | MOQ | Items in Stock (China):MOQ 1 PC Items in Stock (USA):MOQ 1 PC Items Out of Stock: MOQ 100 Pieces |

||

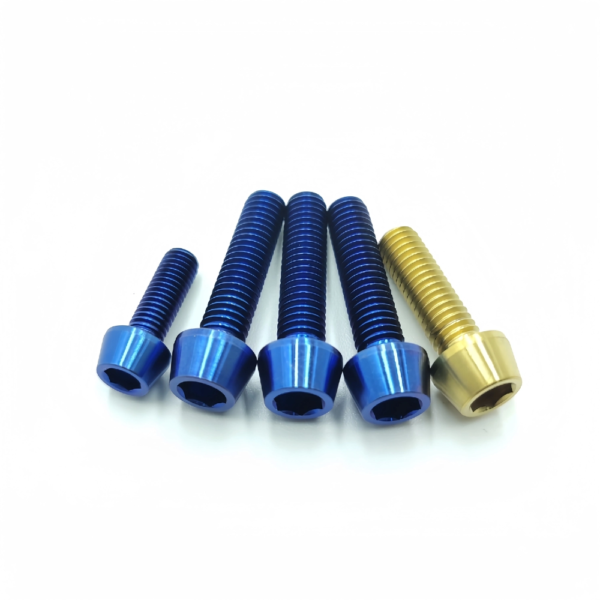

| Length | 12mm~200mm | Thread Spacing | Coarse Thread | Customizable Colors | Natural Color/Black/Burnt Blue/Golden/Rainbow/Purple/Green/Customized color | ||

| Standard | DIN 912 Tapered | Threading | Fully Threaded/Partially Threaded | Surface Treatment | Pickling/Polishing/Anodizing/PVD Coloring | ||

Titanium Tapered Head Socket Cap Screws is a special fastener with high performance. Its head is hex socket tapered, a shape that facilitates better positioning during installation. The hex socket is designed for easy tightening with specific tools, and the titanium material has good strength and corrosion resistance. They are widely used in fields such as aerospace, automobile manufacturing and Marine industry.

Features of Titanium Tapered Head Socket Cap Screws

* Head design advantages: Conical hexagonal head type helps to better fit with the mounting surface during installation, especially in some irregular surfaces or installation positions with a certain inclination. At the same time, the drive style of the hexagon makes the contact area between the screwdriver and the screw head larger, and the torque can be transmitted more evenly during the tightening process, reducing the risk of head wear and screw screw slip.

* Variety of specifications: A wide range of thread sizes from M4 to M36, thread lengths from 12mm to 200mm, to meet different customer needs, but also to adapt to a variety of different connection needs. For thinner connectors, smaller sizes and shorter lengths of screws can be selected; For heavy structural parts, large-size, long-threaded screws can be used to ensure adequate connection strength and stability.

* Wear resistance: Although the surface hardness of titanium alloy is low, its wear resistance is good, and it can reduce wear and loosening in long-term use.

* International Standard Certification: Compliance with the international standard DIN 912 Tapered means that the screw is versatile. In the international scope, screws that meet the standard can be easily assembled with other parts that meet the same standard, reducing the compatibility problems caused by inconsistent standards, and improving the efficiency of production and assembly.

Advantages of Titanium Tapered Head Socket Cap Screws

* Light weight and high strength: the density of titanium metal is low, which can make the screw lighter in the case of ensuring strength. This is particularly beneficial in applications where weight is required, such as aerospace, where weight reduction can improve the performance and efficiency of equipment.

* Strong corrosion resistance: Titanium metal has excellent corrosion resistance and can be used in a variety of harsh environments. Whether it is in a humid, chemically corrosive environment, or in the Marine environment, titanium tapered head socket cap screws can maintain good performance and reduce the impact of rust and corrosion on its structure and function.

* Long service life: strict selection of aviation-grade Ti6AL4V(TC4) titanium alloy material, precision processing technology, to ensure longer product life, lower maintenance costs.

* Very low magnetism: the permeability of titanium alloy is very small, almost negligible, so titanium alloy fasteners are non-magnetic, which can effectively prevent magnetic field interference. This characteristic makes titanium alloy material can be used in avionics equipment.

* Non-toxic: Titanium alloy material is a green material, non-toxic. With the enhancement of health awareness, titanium screws are widely used in medically assisted treatment. Titanium screws even in the human body can also have good compatibility with human tissues and blood. For example, heart stents, intramedullary nails, dental implants, therapeutic instruments and some physiotherapy equipment with more contact with the human body.

Application of Titanium Tapered Head Socket Cap Screws

* Aerospace: Titanium screws are used in the connection assembly of aircraft, spacecraft, etc., which can maintain stable performance under extreme temperature, pressure and corrosion environment.

* Automotive industry: The lightweight characteristics of titanium alloys help to reduce the weight of vehicles and improve fuel efficiency.It is used in the automotive industry to manufacture high-performance engines, racing cars and light vehicles.

* Construction field: Because of the corrosion resistance and high strength of titanium alloy,which make it suitable for some special applications in building structures, such as large machinery, generator sets, etc.

* Medical industry: Because titanium has good biocompatibility, it will not cause allergic reactions or rejection reactions. It is often used in the manufacture of medical devices such as implants, prosthetics and dental equipment.

* Sports equipment: The lightweight and high-strength properties of titanium make it ideal for the manufacture of sports equipment. It is commonly used in golf clubs, tennis rackets and bicycle parts.

* Electronic equipment: Titanium alloy non-magnetic, light weight, high strength, very suitable for use as electronic equipment fasteners. For example, some key components in electronic devices such as mobile phones and computers.

Custom Titanium Tapered Head Socket Cap Screws

We provide personalized customization services to customize thread size, length, surface treatment and packaging according to your needs. Whether it is a special size or a specific function, our engineering team can tailor it for you to ensure that it perfectly matches your project requirements.

* Custom specifications: A wide range of thread sizes from M4 to M36 and thread lengths from 12mm to 200mm to meet different customer needs. At the same time also support customer drawings or samples processing.

* Material and performance customization: According to different grades of titanium alloy materials (such as TA1, TA2, TC4), to customize to meet the high strength, corrosion resistance and lightweight products.

* Custom Surface treatment: according to the needs of customers can do different surface treatment, such as Pickling/Polishing/Anodizing/PVD Coloring, etc.

* Custom color and logo : Customizable colors, such as Natural Color/Black/Burnt Bule/Golden/Rainbow/Purple/Green, etc., to meet customer demand on beauty or logo.

* Packaging and label customization: We can provide personalized packaging materials, labels, etc., according to customer packaging requirements and methods.

Why choose us – a professional titanium bolt manufacturer?

* Rich manufacturing experience: We have many years of titanium alloy processing experience, and have a complete set of production lines and advanced CNC machining equipment. High quality titanium alloy fasteners can be produced efficiently.

* Quality assurance: Products strictly comply with the international standard DIN 912 Tapered, after multiple tests, including raw material testing, size testing, performance testing to ensure that each product can meet customer requirements.

* Price advantage: As a direct manufacturer, we sell directly to customers with transparent prices.

* Fast delivery: We have a sound inventory management and logistics system, from product design to production and delivery to customers, we manage the whole process efficiently to ensure timely delivery.

FAQ of Titanium Tapered Head Socket Cap Screws

Q:Are you a manufacturing company or trade company?

A:We are a manufacturer, we have professional production team and CNC machines.

Q:Will titanium bolts rust?

A: Titanium alloy corrosion resistance is strong, in the wet, there are chemical corrosive substances in the environment or in the Marine environment will not rust.

Q:How long is your delivery time?

A:Generally it is 5-10 days if the goods are in stock.or it is 15-20 days if the good are not in stock.it is according to quantity.

Q:Do you provide samples?Is it free or extra?

A:We could offer the samples for free charge but don’t pay the cost of freight.

Q:What’s your terms of payment?

A:Pay 30% before production, pay 70% before shipment (Payment method T/T, PayPal or other ways you prefer).

Reviews

There are no reviews yet.